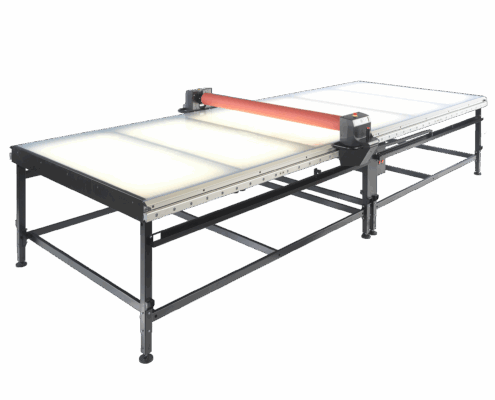

Laminators

Discover top-quality laminating solutions for various applications. Kala offers a range of laminators designed for small businesses to large industrial settings. With their cutting-edge technology, you can achieve precise and professional results on different materials. Neschen laminators are known for their reliability and user-friendly features. Whether you need laminating for documents, photos, or artwork, Neschen has you covered. These laminators are durable and built to last, ensuring long-term performance. Both brands are trusted by professionals worldwide for their efficiency and consistent output. Enhance the longevity and appearance of your prints, graphics, and signage with Kala and Neschen laminators. Explore our site for more information on the available models and find the perfect laminating solution for your needs. Hot and cold laminators are used to apply a protective layer over various materials like paper, photographs, documents, posters, or artwork. The main difference between hot and cold laminators lies in their method of applying the protective layer.

Hot laminators use heat to activate the adhesive on the laminating film, which then binds to the material being laminated. The process involves passing the material through heated rollers that melt the adhesive, ensuring a strong bond between the material and the laminating film. Hot laminators are ideal for items that may be affected by pressure or require a permanent seal.

On the other hand, cold laminators do not use heat during the laminating process. Instead, they rely on pressure-sensitive laminating films or self-adhesive laminating pouches. The material is manually fed through the laminator, and the pressure-sensitive adhesive on the film adheres to the material without the need for heat. Cold laminators are suitable for materials that might be sensitive to heat or for items that are heat-sensitive, such as certain types of ink or thermal paper.

Each has its advantages and best-use scenarios. Hot laminators are often preferred for achieving a strong and permanent bond, while cold laminators are chosen for more delicate materials or when heat might damage the content being laminated.

Explore our site for more information on the available models and find the perfect laminating solution for your needs.